Welcome to Formutech Inc.

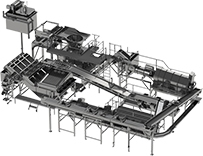

Formutech provides quality service and equipment designed to streamline food processing through maximizing productivity. Located in Prince Edward Island, Formutech is surrounded by an economy driven by the agricultural and fishery industries. Focusing on design and knowledge of its surroundings, Formutech is able to provide custom solutions for optimization within the food processing industry.

As a strategic partner, Formutech provides clients with quality service and products based on research and experience. Combining its knowledge with European technology, equipment and engineering, Formutech is able to guide its clients from the early planning stages through to installation. From sorting, cleaning, grading to packaging, Formutech is able to optimize your production process.

Seafood Expo Global Barcelona - April 23rd -25th, 2024 in Barcelona - Booth 3HH401

Our partner Murre Technologies will participate again in Read more

Seafood Expo North America - March 10th-12th, 2024 in Boston - Booth 2165

Formutech is excited to participate again in Seafood Processing Expo North America, [..]

Read more